Sheet Metal Hole Punching

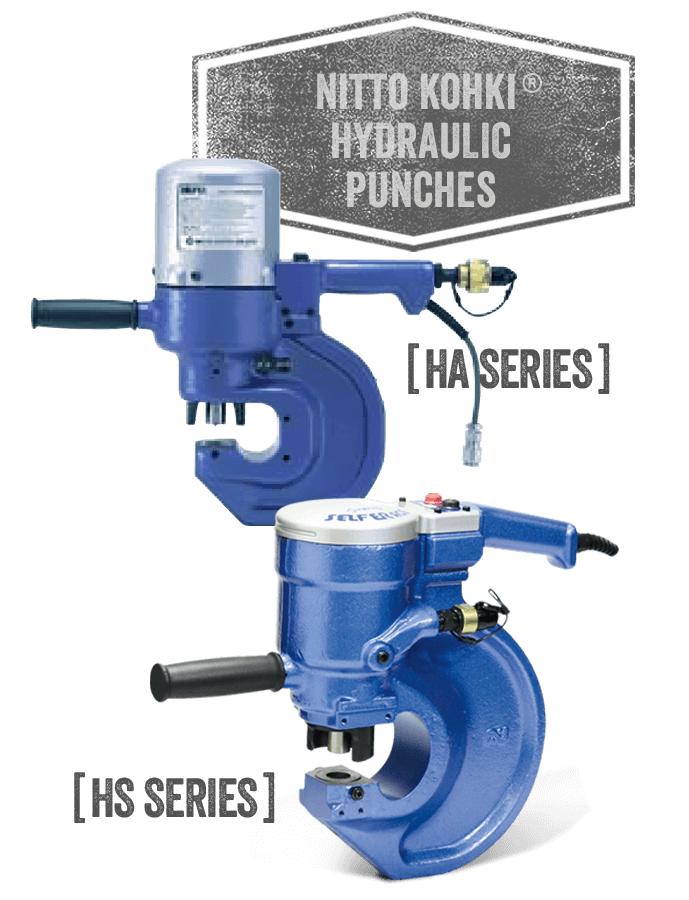

Gulf States Saw & Machine Co. sells portable, double-acting hydraulic punches. They provide a complete automated process of punching and reverting through their inbuilt dexterous control device.

These processed holes can be used to process an unlimited number of holes, and they are completely free of burrs. This makes them unique.